DIY Tapped Horn Subwoofer

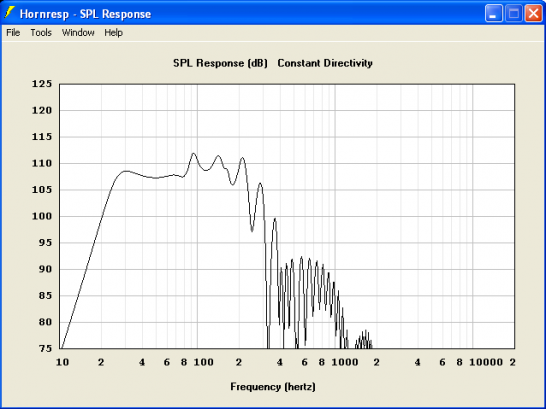

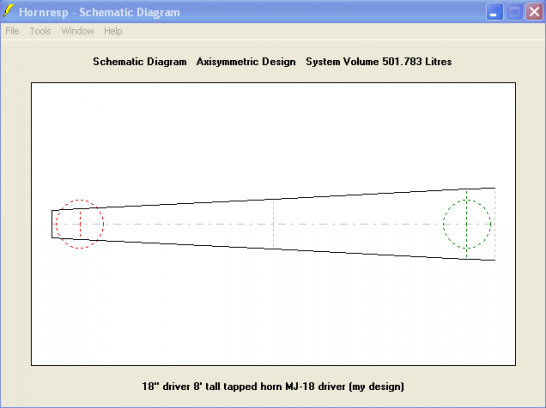

Here stands an eight foot tall bass horn loaded with an 18 inch subwoofer.

This horn is absolutely amazing! I learned about it from an industrious fellow who lives in Australia: William Cowan. I didn't have his horn's dimensions, so I just eyeballed his layout. Rather than reproduce a direct copy, I turned the inner baffle so that instead of running side to side, it runs corner to corner. I've always been a fan of triangular walls in my speaker enclosures. Triangles are strong and don't resonate with standing waves as do parallel walls.

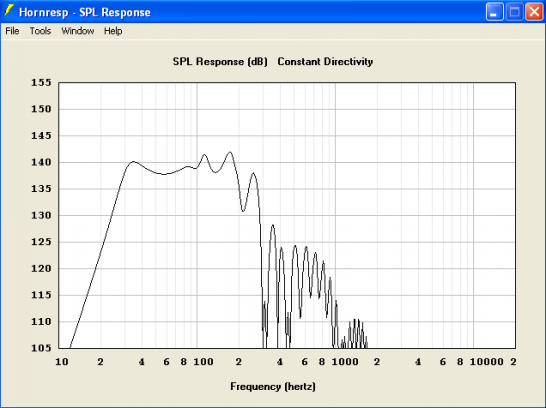

After completing the horn, I hooked it up to the right channel of my 1200 watt subwoofer amplifier. I located a copy of Pink Floyd's "Breath". You know, the song from Dark Side of the Moon that begins with a heartbeat. Well, I'm here to tell you, that song put me in the dog-house with my wife for nearly a week. I suppose that the sound of the house creaking and rattling doesn't impress women the way it does men...

If you ever have the time, inclination, and room, do yourself a favor and fabricate one of these bad boys! You can scale down the drawing to any size woofer you like. A bud of mine is using a Cerwin Vega 10 inch car woofer and it rocks the house down. It can almost keep up with my big fellow.

By the way, one thing that you absolutely must keep in mind: lots of glue and screws! This horn can develop tremendous acoustic pressure and a loose panel will resonate or rattle during a hard kick-drum passage like a loose shutter in a hurricane! I know from experience the frustration of tracking down a rattle--it can drive you nuts. In fact, I ended up using four lengths of 1/2" threaded rod to secure the back of the horn and inner baffle to its bracing. I had to, as the horn actually managed to break the screw and glue bond I originally used. Talk about power!

There's a 10" version available:

Note: